Activities in the field of technological equipment for SHPP are:

• "turnkey" completely technology supplies for SHPP

• partial deliveries (complete electric) "turnkey"

• the supply of certain components (electrical protection systems, control systems, apparatus measuring electrical parameters and other equipment intended for the management of technology SHPP)

Technical specifications of the SHPP control system functions

The number of turbines, generators of the type and nature of operation

• one turbine, generator asynchronous, parallel operation with the national grid

• one turbine, synchronous generator, a parallel operation with the national grid and island grid

• two turbines, generators asynchronous, parallel operation with the national grid

• two turbines, generators, synchronous, parallel operation with the national grid and island grid

• 3 or more turbines, generators asynchronous, parallel operation with the national grid

• 3 or more turbines, generators, synchronous, parallel operation with the national grid and island grid

Automatic Control

Operation sets is fully automated and management concepts designed to be optimally used hydro energetic potential water flow with the minimum requirements for maintenance of equipment. Management sets are made based on programmable logic automaton from companies HONEYWELL, UNITRONICS and SIEMENS according to customers' requirements and demandingness of the applications.

Microprocessor control system provides for automatic operation of MVE with periodic surveillance operator in the optimal mode with regard to the requirement power and water level as follows:

• asynchronous generator automatic connection to the network in reaching the rated speed

• generators automatic synchronization

• generators disconnection from the grid in the event of failure or malfunctioning equipment and turbine shutdown

• turbine automatic starting up to approaching the previous settings after failure subsides

• parametric generator power control - turbine governor opening, depending on the state of water level

• grouped regulation of the turbines

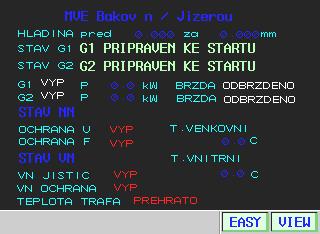

• visualizations on the color graphical display all necessary parameters of the control system (performance, level, temperature, etc.) and the failures states

• record, memory operation (performance, water level - for information 14 days)

• record, memory failures states (99 entries)

• communication with the overall PC as dispatching through ETHERNET

• communications services using GSM reports

The system of the protections

To ensure safe operation of technology the control system works with a system of protections

• Frequency protection and ROCOF protection

• Voltage protection

• Reverse power protection

• Current asymmetry

• Overcurrent protection

• Generator differential protection

• Thermal protection of bearings and winding

• Measurement of vibration

Water level and Power regulation

Assuming the availability of water is possible for individual turbine is keep constant power. The main requirement control system is, however, get the maximum power available in the flow of water. For this reason we use a water level control and output power optimisation.

For run-of-river power stations with a small accumulation of water is always one of a turbine as a regulatory level. Others are running in the towed regulation according to desired performance. The level is kept just below the edge of an overflow weir.

For the dam with a large accumulation of water is used a proportional power control, where the desired outputs of individual generators is proportional to the water level.

Frequency control in the island network  Frequency in an island grid is dependent on the relative outputs of various sources (turbines) and inputs of individual loads on the network. The rapid changes of loads in the island grid with constant outputs of sources (turbines) makes a change of frequency. For keeping the frequency within permitted limits can be either a rapid change of the loads or change the outputs of sources (turbines). For physical reasons, it is not usually possible rapid change of the outputs of sources (turbines). The only way a quickly change a loads is use the electronic flywheel. Setting the appropriate parameters for flywheel is possible to keep a reserve power within the limits of 0-110% of the power source. Using an electronic flywheel significantly improves the stability of the island grid and extending the life of the governors of the water turbines.

Frequency in an island grid is dependent on the relative outputs of various sources (turbines) and inputs of individual loads on the network. The rapid changes of loads in the island grid with constant outputs of sources (turbines) makes a change of frequency. For keeping the frequency within permitted limits can be either a rapid change of the loads or change the outputs of sources (turbines). For physical reasons, it is not usually possible rapid change of the outputs of sources (turbines). The only way a quickly change a loads is use the electronic flywheel. Setting the appropriate parameters for flywheel is possible to keep a reserve power within the limits of 0-110% of the power source. Using an electronic flywheel significantly improves the stability of the island grid and extending the life of the governors of the water turbines.

Optimizing running turbines

If the SHPP installed two or more turbines (usually two), we used a turbines output optimization, for maximization the power generation with existing water flow. This is achieved optimal distribution of output power (opening) turbines, to work with maximum effectiveness. Optimizing then compared with traditional regulation provides additional 10 or 15 percent of produced annual energy.

Management of trash rack cleaning machine

Management of the trash rack cleaning machine depends on the specific implementation of the cleaning machines and the number of measurement levels and is generally an individual for the power plant. Cleaning of the trash racks is carried out depending on the difference between the levels in front of rack and behind, the elapsed time between cycles or a combination of both. The procedure is carried outeither in the common PLC for generators and cleaning machine or a separate PLC.

Delivery also includes a local switchboard for the manual control of different arms of the cleaning machine and hydraulic power pack.

The types of control

The used type of control is depends on the control system and customer requirements.

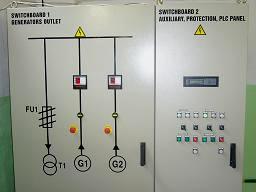

• Local control of the switchboard

It is installed directly on the control panel and can be done either buttons or using a graphical "touch-screen" display control.

• Local control of the control room operator

It is located at a distance of several metres to several hundred meters from the cabinet. Interconnection is implemented serial communication line with metallic cable, Ethernet optics or wireless Wi-Fi connections.

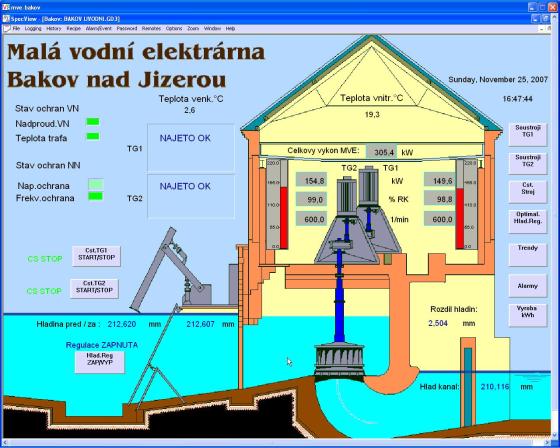

By default, we use the PC with LCD display, the SCADA system, which are generally implemented the following displays: Overall, Turbine display parameters, Headline alarms, Trends of the important variables.

• Remote control over the INTERNET or using the GSM communications

It is located at any distance from hydro power station and can be implemented in two ways.

The first way is through the interconnection of mobile networks. If the place of power signal mobile operator, this solution provides the following features:

-- Using SCADA display monitor and manage the turbines

-- Obtain information and guidance to enter using a mobile phone and SMS messages

The management system in case of alarm sends an SMS to selected telephone numbers with a description of alarm. The resulting breakdown the user is informed almost immediately and may take appropriate arrangements.

The second way is to connect the Internet, which requires a similar line, or ADSL connections in the power plant site. This method allows the connection to the control system and subsequent control by the TCP IP protocol.

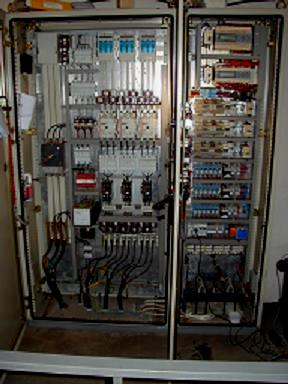

Hardware

The management system can be realized using different hardware. Our most common solution is to use SHC Controller, which was specifically designed for this purpose and used for several dozen applications. In addition, we have rich experience with the use of control systems UNITRONICS Vision and Siemens SIMATIC S7-200 for smaller applications, and Honeywell HC 900 for the largest application.

For local and remote control we use PC with its own software system SCADA.